Optimize and Protect Your Mechanical Assets

We specialize in maintaining vital mechanical equipment such as motors, jigs, and assembly machines, ensuring that every component operates at peak efficiency.

With our dedicated approach, we help manufacturers avoid costly downtimes, extend equipment lifespan, and sustain consistent production quality.

Motors

Motors are the heartbeat of industrial machinery, powering everything from conveyor systems to automated robots. To keep motors performing optimally, Tempus provides routine inspections, lubrication, and precision alignment services, ensuring reduced friction and extending motor lifespan. Should a breakdown occur, Tempus responds promptly, diagnosing and repairing motor issues to minimize downtime. Our team also offers predictive diagnostics, tracking motor performance to identify potential issues before they disrupt operations.

-

AC Induction Motors

-

Servo

-

Stepper

-

PMSM

-

DC & Brushless DC

Jigs

In high-precision manufacturing, jigs are indispensable for maintaining alignment and accuracy in production tasks, from welding to assembly. Tempus supports manufacturers by regularly calibrating, cleaning, and inspecting jigs to prevent wear and misalignment. We understand the critical role jigs play in ensuring consistency and quality, and our rapid response team is equipped to repair or replace damaged jigs, keeping production on track with minimal disruption.

-

Drilling

-

Assembly

-

Welding

-

Inspection

-

CNC and Milling

-

Robotic Assembly

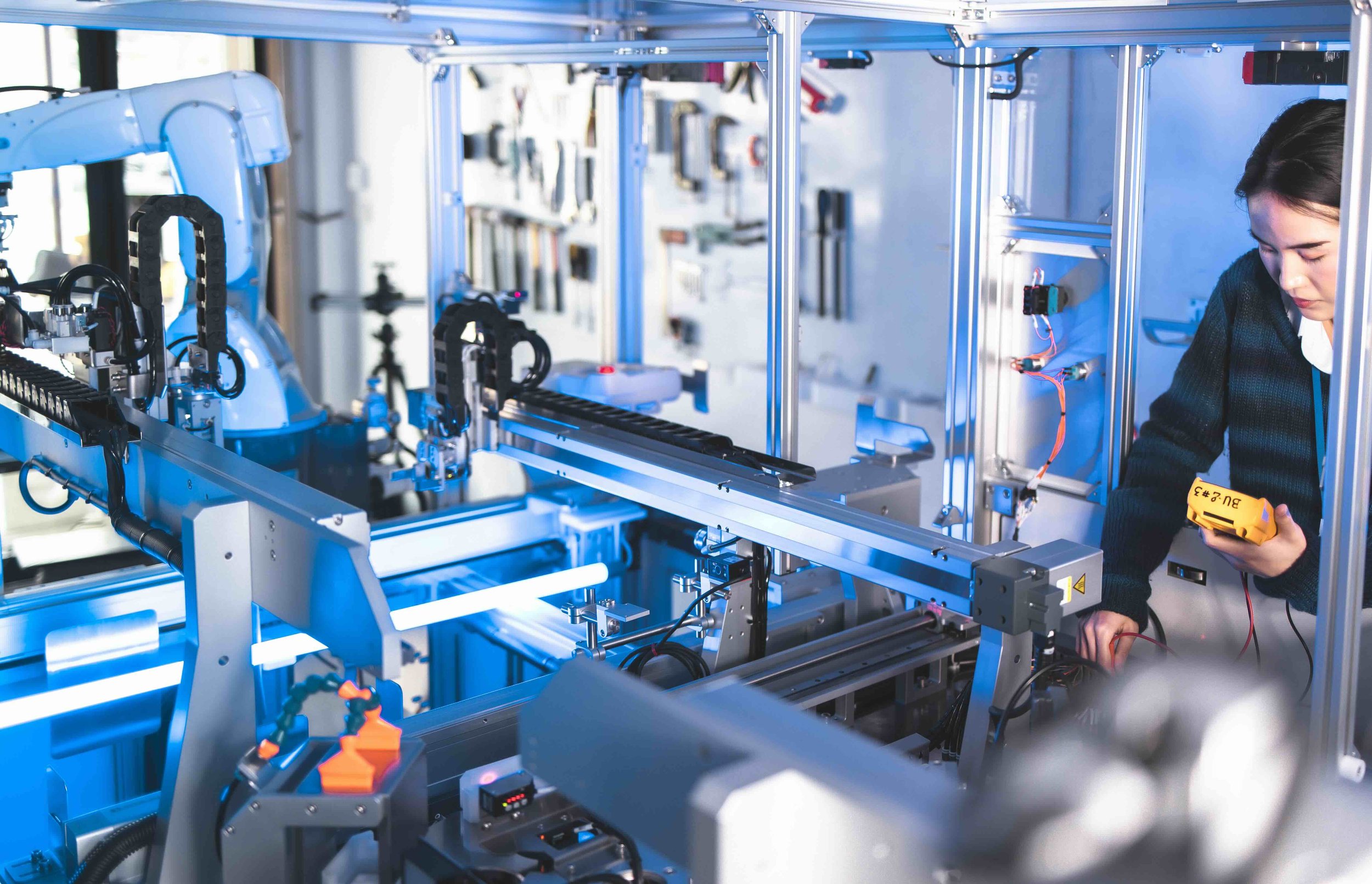

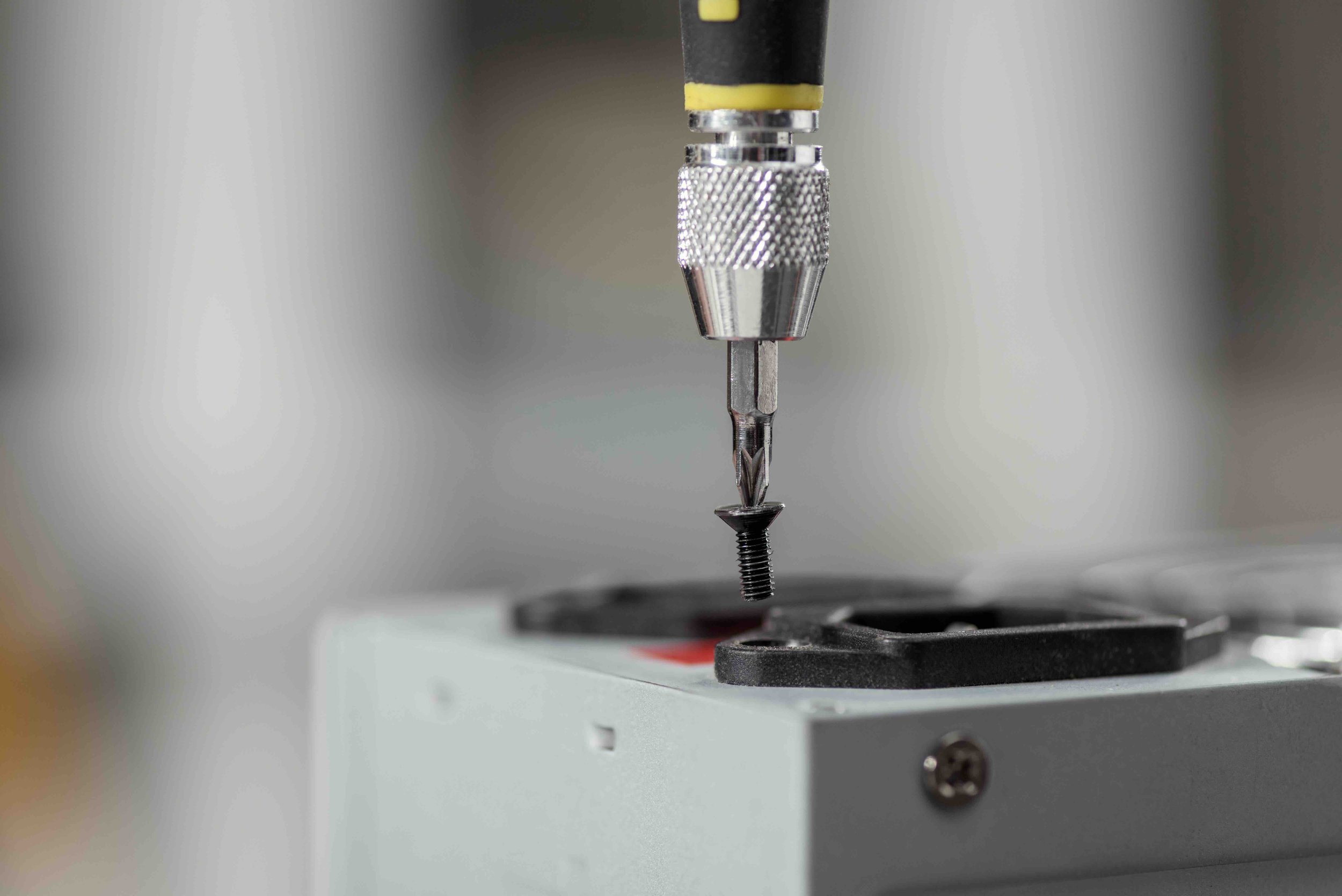

Assembly Machines

Automated assembly machines are essential for high-efficiency manufacturing, assembling components with speed and precision. Tempus keeps these machines operational through proactive maintenance, including regular checks on moving parts, lubrication, and software updates for machines with programmable controls. In the event of a breakdown, Tempus technicians provide swift repairs and replacements for key components, from fastening systems to sensor calibrations, ensuring your assembly lines stay productive.

-

Screw Fastening

-

Pick-and-Place

-

Heat Staking and Ultrasonic

-

Press-Fit Assembly

-

Vision-Guide Robotic

Enhanced Safety

Regular maintenance helps identify and address potential safety hazards, protecting your operators and preventing accidents.

Performance

Well-maintained equipment operates at peak efficiency, maximizing productivity and reducing fuel consumption.

Longevity

Proper maintenance extends the lifespan of your heavy equipment, delaying the need for costly replacements.

Resale Value

A well-maintained machine retains its value, making it easier to sell or trade in when the time comes.

Why Choose Tempus?

We understand the unique challenges of manufacturing. Whether you need support in IT systems, facility management, or industrial machine maintenance and installation, our team is dedicated to helping you achieve operational success. We offer solutions that ensure efficiency and security through advanced technologies and skilled professionals, and a customer-centric approach. You focus on growth and innovation while we take care of the rest.