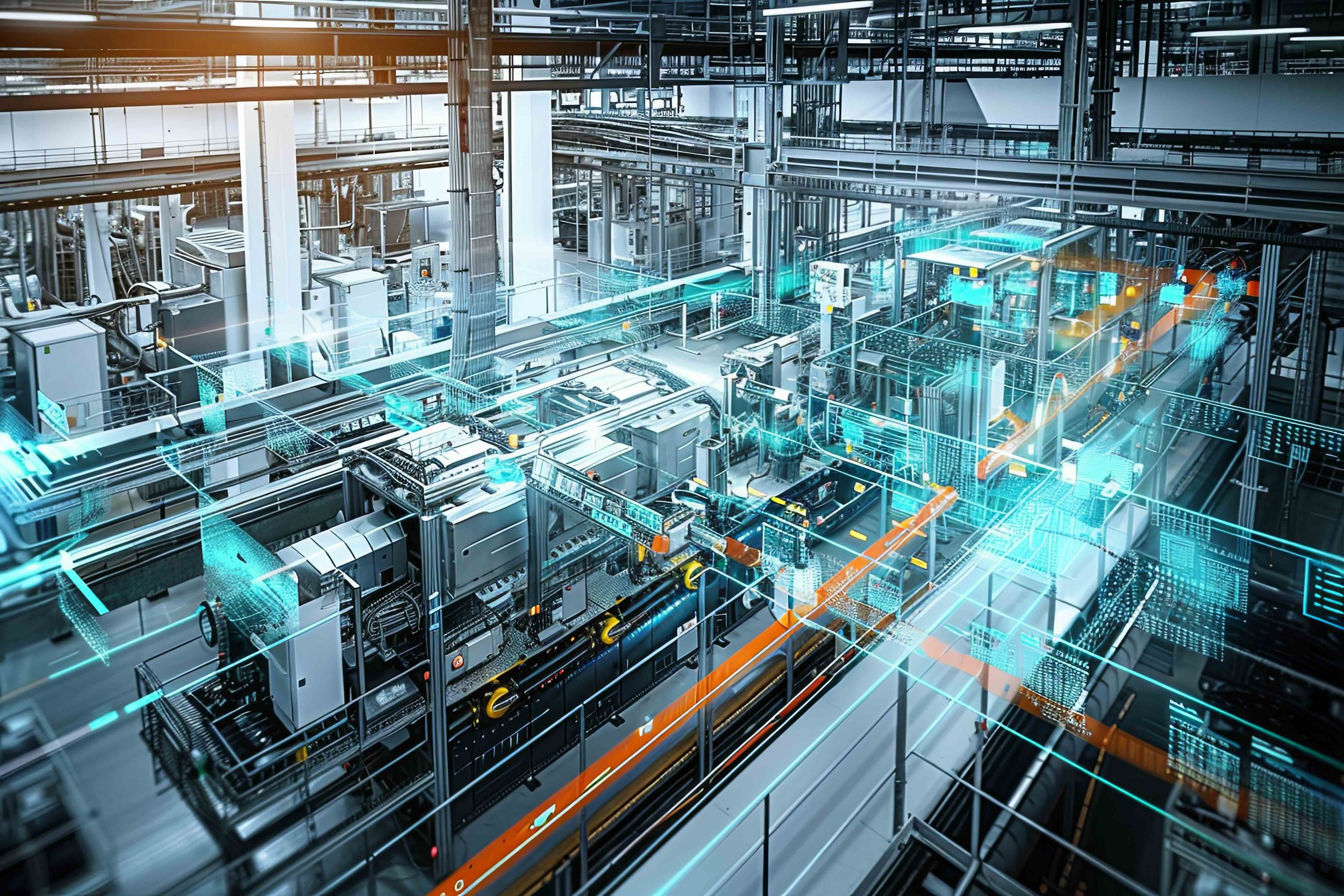

Manufacturing Execution System

Tempus empowers manufacturers to enhance efficiency, improve quality, and reduce downtime by capturing and analyzing real-time data for data-driven decision-making. In the midst of supply chain constraints, skilled labor shortages, and geopolitical challenges, embracing smart manufacturing technologies is crucial for staying competitive and maintaining overall productivity.

Real-time Visibility and Control for Manufacturing Excellence

Manufacturing Execution Systems (MES) are the backbone of modern manufacturing, offering real-time visibility into every stage of production, from raw materials to finished goods. By bridging the gap between the factory floor and management systems, MES enables seamless coordination, control, and optimization of operations. With functionalities like production monitoring, condition monitoring, predictive maintenance, and process optimization, MES empowers data-driven decision-making. Adopting MES is a key step in digital transformation, providing the essential benefit of real-time visibility and control to boost productivity and performance.

Already have MES but need a new one?

MES holds a critical position for manufacturers because it bridges the gap between high-level business applications like ERP and the Industrial Control Systems like SCADA/HMI. While ERP systems help with resource allocation, they lack the granularity of MES, which provides real-time, even minute-to-minute, resource scheduling, execution, and dispatch.

-

In-Depth Understanding of Your Needs

We take the time to comprehend your manufacturing processes, challenges, and objectives. We consider your existing machinery, IT infrastructure, and future growth plans to ensure the MES solution is scalable and adaptable.

-

Requirements Definition

We assist in clearly defining your MES requirements, crafting comprehensive RFIs and RFPs, and developing insightful demo scripts. This ensures you have a solid foundation for evaluating vendors and making informed decisions.

-

Tailored MES Solution

We'll help you identify the specific MES capabilities that will drive the most value for your business. This includes considering production monitoring, quality control, inventory management, and other critical functionalities.

-

Expert Vendor Selection

We leverage our industry expertise and vendor relationships to guide you through the selection process, ensuring you choose a solution that meets both your technical and budgetary requirements.

-

Seamless Integration

We understand that MES implementation impacts your entire organization. Our change management strategies minimize disruption, ensuring all departments are aligned and equipped to embrace the new system.

-

Maximized ROI

With a focus on defining key performance indicators (KPIs) and aligning MES capabilities with your business goals, we help you maximize the return on your investment.

Advanced Analytics and AI for Data-Driven Manufacturing

Tempus leverages advanced analytics and AI to empower your decision-making. By integrating these capabilities into your MES platform, we provide valuable insights, predictive maintenance schedules, and proactive recommendations. This enables you to anticipate and address issues before they escalate, optimizing your processes for continuous improvement.

Cloud-Based MES Solutions for Scalability and Flexibility

We understand the importance of scalability and accessibility in today's fast-paced manufacturing environment. Our cloud-based MES solutions offer the flexibility and agility you need, eliminating the constraints of on-premises infrastructure. With real-time data sharing, remote access, and seamless collaboration, you can stay connected to your operations from anywhere, anytime.

Mobility for On-the-Go Decision Making

Empower your authorized personnel with mobile access to critical MES data and functionalities. This ensures informed and efficient decision-making, even when they're away from their desks.

MES links production to executive decision-making by offering real-time control, tracking, and documentation of the entire production process, from raw materials to finished goods. This real-time data, especially when visualized on dashboards, provides an accurate, up-to-the-minute view of plant operations, allowing for comparison against historical performance and production targets.

Manufacturing Automation

Through real-time KPI dashboards, alarms, and notifications, alongside intuitive operator interfaces, manufacturing automation capabilities offer enhanced visibility into your production processes. This allows for immediate response to any issues that may arise and continuous monitoring of key indicators, ultimately leading to optimized operations.

Production Management

By tracking scrap, OEE, yield, and MRO rejects, production management capabilities within an MES enable you to maximize your production capacity. Gaining insights into production efficiency allows you to reduce downtime and optimize machine performance, driving higher productivity and profitability.

Quality Management

Integrated monitoring and control systems within an MES ensure your products consistently meet quality standards. This leads to a significant increase in product quality, reduction in waste, and improved compliance with industry regulations.

Inventory Management

MES offers comprehensive inventory management, encompassing traceability, product genealogy, serialized part management, cycle counts, shipment container tracking, and lot traceability. These capabilities improve inventory accuracy, reduce instances of stockouts and overages, and ensure seamless traceability throughout your entire supply chain.

Tool Management

By effectively managing tool usage, maintenance schedules, and performance metrics, tool management features within an MES help you extend tool life, reduce maintenance costs, and ensure that the right tools are available and in optimal condition whenever they're needed

Cyber Security

Protecting your network from unauthorized access is paramount. We work collaboratively to model your facility's assets, creating a framework for role-based security. This ensures secure remote connections and credential-based access, guaranteeing the right people have access to the right information and equipment across your facility.

Your Comprehensive Manufacturing Partner

Beyond MES implementation, we offer a holistic suite of services tailored to your manufacturing needs. From machine installation and plant setup to ongoing maintenance and equipment relocation, Tempus is your one-stop solution for achieving manufacturing excellence.

Ready to unlock Turn-Key industrial machine installation?

Don’t want to manage people?

Elevate your manufacturing operations with data-driven decision-making.

Find out how we can empower your manufacturing excellence.